Smart, scalable, and future-proof solutions for sorting, handling and advanced automation.

A comprehensive ecosystem of smart, automated solutions. Fives designs and supplies a global portfolio of value-added, customized solutions for sorting, handling, industrial cleaning and automation. Our integrated offerings bring together advanced technologies, proprietary software and aftermarket services for supply chain transformation. As a global organization, we can support our customers’ operations in each key region, rapidly responding to all applications that require accelerated, smart automation solutions anywhere in the world.

Airport

We serve the airport sector with unique baggage handling, early baggage storage and hold baggage screening solutions.

E-Commerce

The world’s leading e-commerce retailers and distributors choose us for our decades of experience in providing scalable, high-performance systems to optimize order fulfillment.

Manufacturing & assembly

Our manufacturing and assembly offer includes a range of flexible, modular, innovative and future-proof solutions.

Assembly Solutions Conveying solutions Robotic Handling Wood Panel and Furniture Solutions

Parcel & postal

40 years of industry intelligence is embedded in our integrated parcel processing and sorting solutions to serve the postal and courier markets.

Air gateway process Irregular distribution Parcel Distribution Small parcel distribution

Retail & Fast-Moving Consumer Goods (FMCG)

Our distribution chain expertise covers both processing technologies and intralogistics solutions from ultra-fresh products to packaged foods.

Fresh and Ultra-fresh FoodFresh Food DistributionOrder Picking Robotics

Autonomous Mobile Robots (AMR)

Our autonomous mobile robots effectively manage complex processes, even in small and oddly shaped spaces.

ASRS

Our advanced, high throughput ASRS systems help our customer in their storage, buffering and sequencing needs.

Conveyors

We design modular and robust conveyor technologies capable of sustaining high speeds without sacrificing reliability.

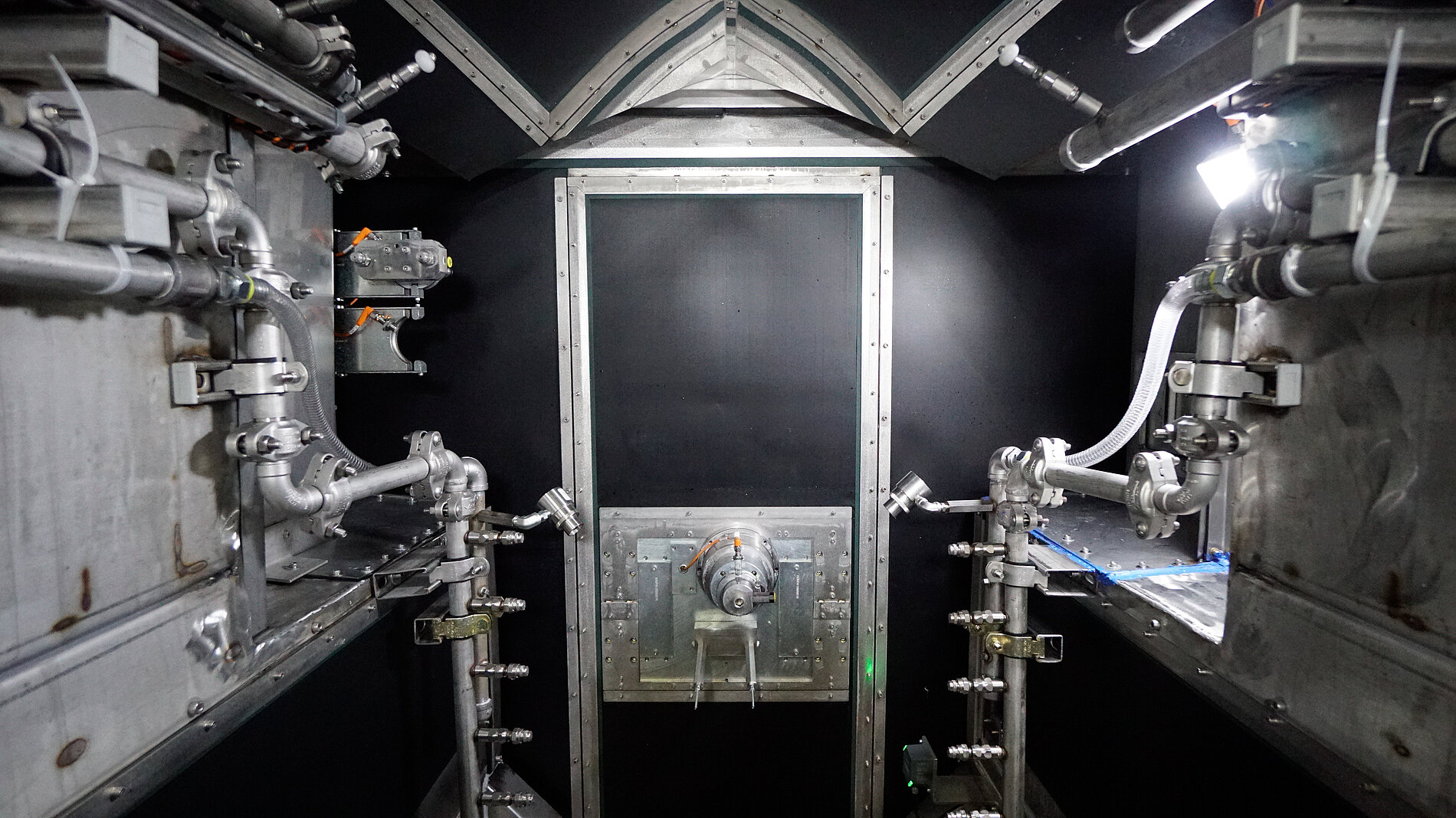

Industrial washers

Fives offers a full line of industrial part washing, drying, and surface finishing technologies to support critical cleanliness requirements of the automotive powertrain market.

InspectionWash Front-Loaded Industrial Parts Washer RoboWash Robotic Industrial Parts Washer RotaryPartWash Industrial Parts Washer SmartWash 5-Axis NC Industrial Parts Washer TunnelWash Industrial Parts Washer

Palletizing/

Depalletizing

We develop anthropomorphic and linear axis robots for palletization, depalletization and mixed case automatic order picking (OPR).

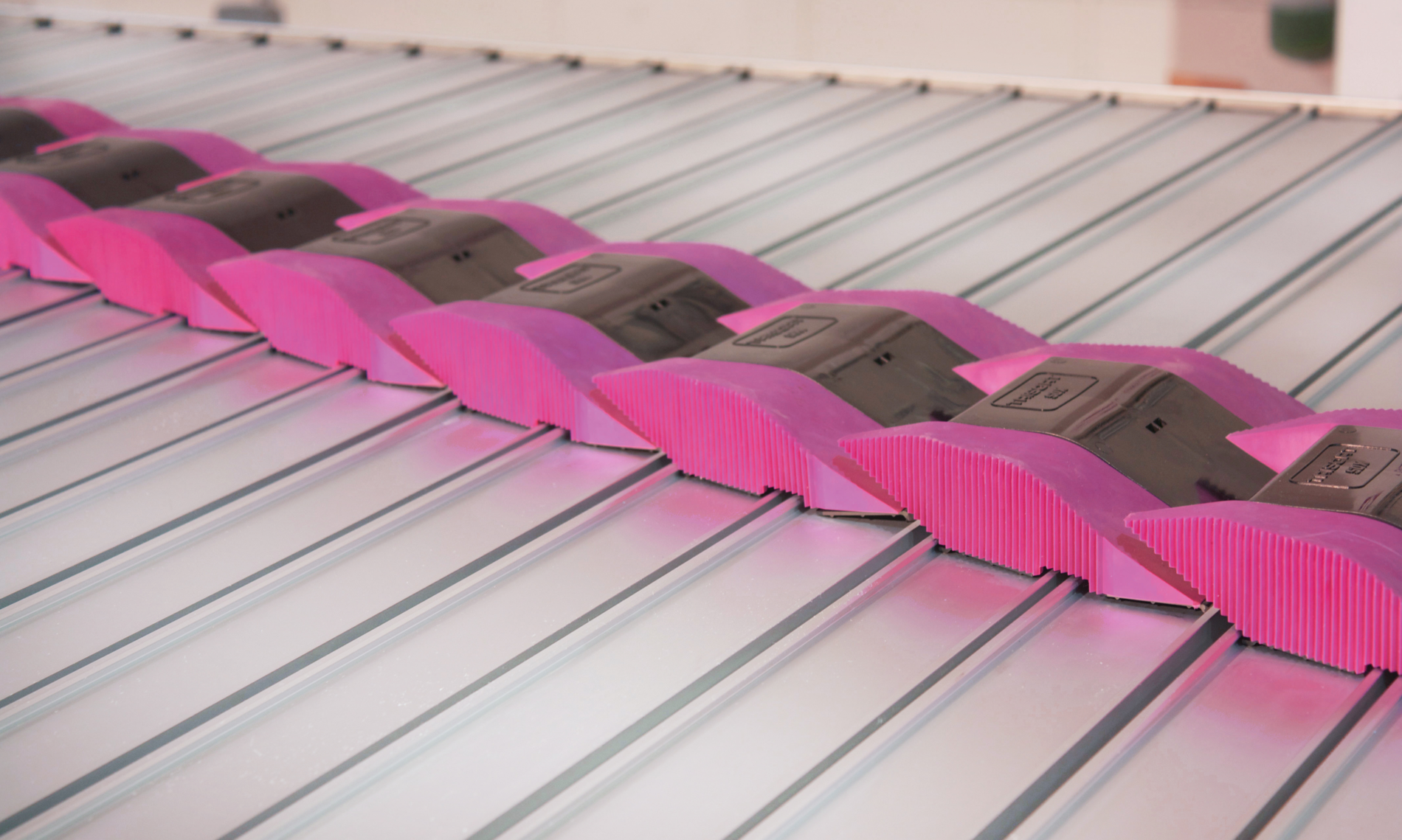

Singulators

Equipped with vision and advanced flow management software, our line of packet and parcel singulators offer industry-leading throughput and singulation accuracy for mixed product streams.

ACCORD™ Packet Singulator LPS-70™ Linear Parcel Singulator SOLI-XK2™ Parcel Singulator SOLI-Modular™ Singulator

Sorters

Installed in critical sorting centers worldwide, our sorters enhance reliability, redundancy and accuracy.

GENI-Belt Cross-Belt Sorter GENI-Flex™ Modular Solution Irregular Sorter PARA-Push™ Baggage Diverter Swiveler Wheel Diverter TRI-Sort SDX+P™ Linear Parcel Shoe Sorter

Services

Fives helps customers operate, optimize and evolve their businesses through a comprehensive range of specialist services.

ENSURE RAPID START-UP

Fives ensures clients’ installations rapidly reach maximum operating capacity without compromising safety

OPTIMIZE YOUR PRODUCTION

Our experts provide constant operational support to enhance machine productivity, boost uptime and ensure compliance.

INCREASE PRODUCTIVITY OF YOUR ASSETS

Leverage Fives’ proprietary digital solutions to increase productivity from your assets and reduce costs.

FIVES REMOTE SERVICES ANYWHERE, ANYTIME

Wherever you are, Fives Support Team is available 24/7 to support, leveraging Fives Remote Services capabilities, including app.

UPGRADE YOUR INSTALLATION

Fives leverages latest technologies to help you meet evolving needs, throughout the lifecycle of your installation.

ANTICIPATE END-OF-LIFE

We help our customers reduce risks of obsolescence and eventually relocate or decommission systems

Our latest news & events

Fives will be present at the SITL tradeshow, from March 19 to 21, at Paris Nord Villepinte, in booth K018 Hall 7 of HIK Robot, a specialized provider of mobile robotics (AMR) and industrial vision…

DB SCHENKER in France, one of the leading global logistics service providers, has awarded Fives Syleps with a contract for the design and installation of a new mechanized and automated logistics…